Page 3 of 8

Re: Clark's Spinning Block vs The Dubber

Posted: Sun Nov 01, 2015 4:44 pm

by letumgo

I say go for it! I look forward to hearing what you come up with.

Re: Clark's Spinning Block vs The Dubber

Posted: Sun Nov 01, 2015 8:46 pm

by crazy4oldcars

I love a good prototyping project. I look forward to hearing what you come up with.

As an aside,(

http://www.jsflyfishing.com/fly-furnitu ... brush-tool ) it may have already been done. I thought I had shown this here before, but I couldn't find it.

Kirk

Re: Clark's Spinning Block vs The Dubber

Posted: Mon Nov 02, 2015 9:05 am

by Tom Smithwick

I will get busy on the prototype. It's going to be more elaborate than that rig, Kirk, and will spin from both ends at once. I have the design all worked out, it's just a matter of finding or making the right stuff at this point. I'll post it here in a week or so.

Re: Clark's Spinning Block vs The Dubber

Posted: Mon Nov 02, 2015 1:39 pm

by crazy4oldcars

I one of my former lives, I was working for an engineer, and we were designing a new generation of fire fighting nozzles. Not the hand-held ones, but the big, high-flow trailer- and truck-mounted ones.

That was a fun job. We spent all day playing with really big squirt guns, lol. I miss it sometimes, but then I remember going out to test prototypes in 30 degree weather ans reconsider.

I look forward to living vicariously thru your efforts.

Kirk

Re: Clark's Spinning Block vs The Dubber

Posted: Mon Nov 02, 2015 2:12 pm

by Smuggler

I for one can't wait to see your outcome Tom. This topic bloomed into something special.

Re: Clark's Spinning Block vs The Dubber

Posted: Thu Nov 05, 2015 2:01 pm

by Tom Smithwick

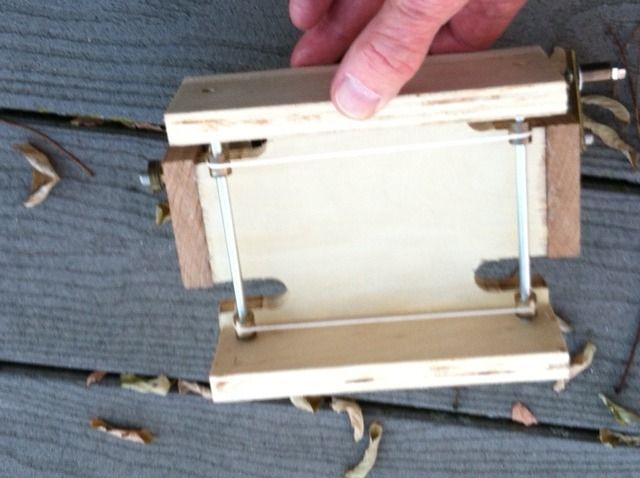

OK - Here's the basic mechanism. The drive cord causes the hooks carrying the thread to counter rotate, twisting either end of the thread loop evenly.

A look at the idler pulleys that guide the belt under the machine.

Re: Clark's Spinning Block vs The Dubber

Posted: Thu Nov 05, 2015 2:37 pm

by Tom Smithwick

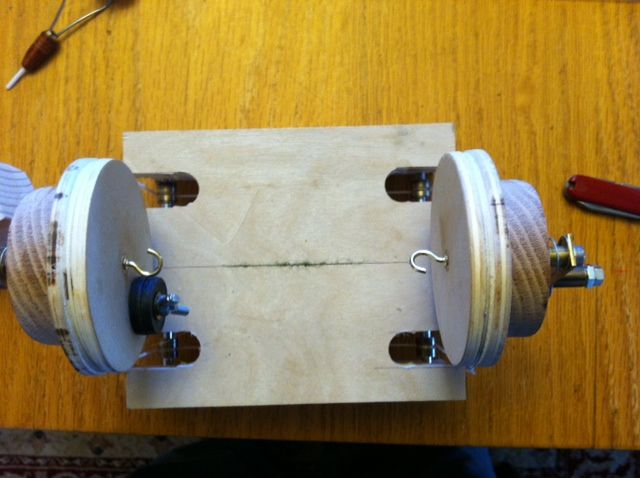

OK - The main drive pulleys are 3' diameter, sawed from 1/2" plywood and sanded smooth. A V groove was cut into them to accommodate the drive belt. The idler pulleys are lathe made, also V grooved for the belt.

The black thing on the far pulley is just two rubber washers to grab the thread ends like a sewing machine tensioner. Both of the main axles are lightly spring loaded, allowing the hooks to advance a bit as the thread is twisted. That is to prevent breaking the thread when winding. I still need to make the removable dubbing block, and I may add another idler pulley under the machine on an adjustable arm to act as a belt tensioner.

In use, the idea is to pinch the thread end into the washers, through the hook and across the machine to the other hook and let the bobbin hang. Spread the fur on the dubbing block as usual, then bring the bobbin over to the first hook and into the washers and clip off the bobbin. Take a couple twists with the block in place to trap the fur, then remove the block and twist freely.

Most of what you see is made from scrap already in the shop. The only things I had to buy were the springs and the .187 steel rod that holds the idler pulleys. None of the dimensions are critical, and I have a feeling I could have found ready made pulleys, etc. if I had looked hard enough.

As I said earlier, I have no interest in making these things, and anyone is free to copy, adapt, and otherwise use the concept if they want to try it.

Re: Clark's Spinning Block vs The Dubber

Posted: Fri Nov 06, 2015 8:01 am

by tie2fish

Very clever, Tom. We suspected after seeing your rod windings rig at Allenberry that you know your way around a workshop.

Re: Clark's Spinning Block vs The Dubber

Posted: Fri Nov 06, 2015 9:18 am

by Tom Smithwick

Thanks Bill - I must be losing it. I thought I posted this yesterday. First body off the twister. It works.

Re: Clark's Spinning Block vs The Dubber

Posted: Fri Nov 06, 2015 9:41 am

by tie2fish

Surprised? Not!